BREADCRUMB Case study

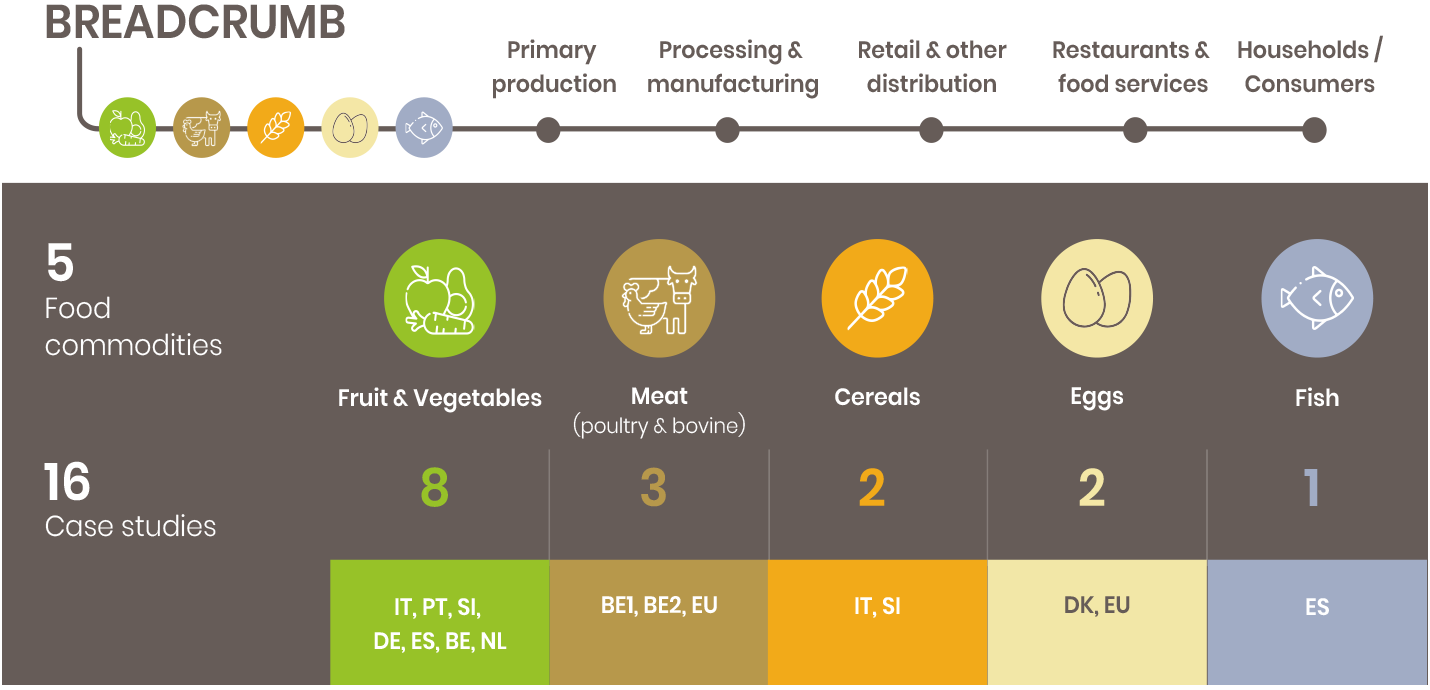

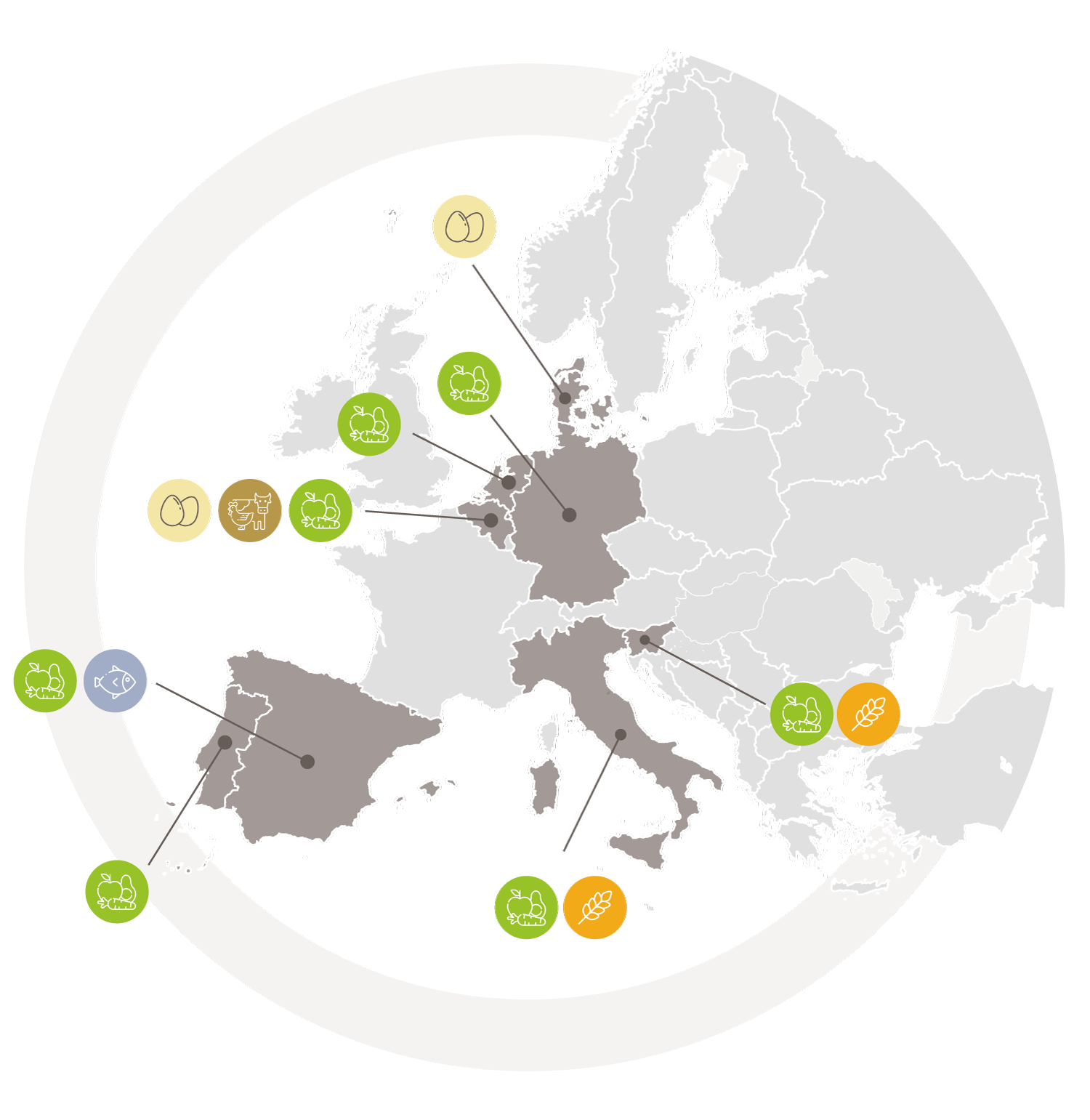

The BREADCRUMB project aims to understand food waste (FW) caused by food marketing standards (FMS) and propose interventions to balance FW reduction. The project investigates five key commodities: fruits and vegetables, meat, cereals, fish, and eggs.

In total, 16 multi-actor case studies (CSs) in different EU countries.

Below is an overview of each case study.

Fruit and vegetables sector

Fruits and vegetables are some of the most commonly wasted foods in Europe, often rejected because they don’t look “perfect.” From oddly shaped carrots to slightly green lemons, food marketing standards focus on appearance and shelf life create barriers for many edible products. BREADCRUMB’s case studies in this sector explore how farmers, processors, retailers, and food service providers are tackling these challenges—by finding creative uses for surplus, rethinking packaging and presentation, and working to change how “quality” is defined.

Natura Nuova

Product(s): Apple, pear, apricot, peach, plum, fruit purées and smoothies

Value Chain Stages: Primary production, Processing, Distribution

Data Collection: in depth interviews, internal data

This case study explores how fresh and processed fruits are affected by marketing rules related to appearance and shelf life. In Italy, Natura Nuova collaborates closely with local farmers and fruit distributors to produce fruit purées and smoothies. However, strict requirements—like how fruit looks or how long processed products last—often lead to perfectly edible products being rejected. Through interviews with local producers and distributors, Natura Nuova examined where waste happens and how it might be reduced. One of the key findings is that products slightly outside the expected standards can still be safely and tastefully used in new products—supporting a zero-waste business model.

Sonae Group

Product(s): Lettuce, tomato, carrot, citrus fruits, bananas, red fruits, apple Gala, pear Rocha

Value Chain Stages: Primary production, Processing, Retail

Data Collection: in-depth interviews, internal retailer data

In Portugal, the retail company MC is working to reduce waste from fruits and vegetables by rethinking how these products are handled along the supply chain—from farms to stores. Some fruits and vegetables are discarded simply because they’re slightly too small or have surface imperfections. This case study highlights several creative solutions, such as developing jam and chutney from overripe produce. MC also launched a “Zero Waste” product line and donation programmes to give food a second chance. Their work shows that with better planning and flexibility, food waste in supermarkets can be greatly reduced.

Zelena Tocka

Product(s): Apples, onions, potatoes, tomatoes, zucchini

Value Chain Stages: Primary production, Processing, Retail, Food service

Data Collection: in-depth interviews

Zelena Tocka, a Slovenian company working with farmers, investigated why certain fruits and vegetables are rejected before even reaching the shops. The biggest issue? Products that don’t “look right”—like odd-shaped apples or small zucchinis—are often discarded. This case study focused on finding ways to reduce that waste, such as raising awareness about the value of “ugly” produce and offering alternative uses like preserves or fruit strips. The team worked closely with farmers and processors to see how appearance standards affect waste and how changing our expectations could make a big difference.

Mensana

Product(s): Lettuce, tomatoes, potatoes, apples, onions, pumpkins, cabbage

Value Chain Stages: Primary production, Processing, Food service

Data Collection: in-depth interviews

In this case, the spotlight is on restaurants and food services. Mensana, which runs restaurant, looked at the types of fruits and vegetables they use most and how much of them are thrown away. They found that even minor imperfections or size differences in

Lehmann Natur

Product(s): Limes, lemons, tomatoes, cucumbers, bell peppers

Value Chain Stages: Primary production, Wholesaler, Retail

Data Collection: Din-depth interviews, internal complaint data

At Lehmann Natur, a wholesaler of organic produce, fruits and vegetables often go to waste not because they’re bad—but because they don’t meet visual expectations. This includes green lemons (which are still ripe) or cucumbers with soft spots. Sometimes, entire shipments are rejected because they don’t look “perfect.” In this case study, Lehmann Natur collected internal data and spoke with their suppliers to find out where and why this waste occurs. Their efforts now focus on improving sorting processes and convincing retailers—and eventually consumers—that fruit and vegetables don’t have to look flawless to be delicious and safe to eat.

ANECOOP

Product(s): Clementines, mandarins, oranges, kaki (persimmon)

Value Chain Stages: Primary production, Processing

Data Collection: in-depth interviews

ANECOOP is a large Spanish cooperative that supplies fruits across Europe. In this case, they focused on citrus fruits and persimmons, which are often downgraded due to minor defects like spots on the peel or uneven colouring. ANECOOP explored how these “second-class” fruits are used—for example, in juice production or animal feed—but noted that these options rarely cover the original production costs. By working with farmers and packers, the cooperative is also developing treatments to reduce spoilage and testing ways to use more of the harvested fruit. Their goal is to help growers and reduce unnecessary waste by giving more value to the full harvest.

ILVO

Product(s): Soft fruit (Strawberries, Blueberries, Raspberries)

Value Chain Stages: Primary production, Distribution, Retail, Matchmaking platform

Data Collection: In-depth interviews

ILVO conducted interviews in Flanders with different food chain actors working with soft fruit. The focus was to identify the food waste occurring at the different stages of the supply chain. They also examined the different food marketing standards that these actors need to apply and tried to understand the relationship with food waste. Furthermore, they looked into the valorisation routes of suboptimal products.

ILVO

Product(s): Tomatoes & bell peppers

Value Chain Stages: Primary production, Processing, wholesaler, stakeholder organisation, matchmaking platform

Data Collection: In-depth interviews

Tomatoes and bell peppers are key export products, supported by the Netherlands’ strategic location and efficient logistics. This has made the country a world leader in the production of these crops, leveraging advanced greenhouse technology to achieve high yields despite limited arable land. ILVO conducted interviews with various actors in the food supply chain. This case study examined food waste along the chain, the methods used to measure it, different FW estimates and its relationship to food marketing standards. It also explored the different reasons for product rejection at various stages of the supply chain.

Meat sector

The meat sector faces a unique challenge: while food safety is critical, a growing number of food marketing standards focus on appearance, shape, or strict classifications that can lead to valuable cuts being downgraded or wasted. In these case studies, meat producers and processors explore how these standards impact beef, pork, poultry, and processed meats. By studying the causes and exploring more flexible approaches, BREADCRUMB partners aim to reduce unnecessary waste while still ensuring quality and safety.

FENAVIAN

Product(s): Chicken fillet, bacon, cooked and raw ham, pâté, salami

Value Chain Stages: Processing, Manufacturing, Distribution

Data Collection: in-depth interviews, surveys

This case study focuses on processed meats produced in Belgium, including cold cuts and ready-to-eat products. FENAVIAN, the national federation of meat processors, worked with companies to understand how certain marketing requirements—such as uniform slices or perfect texture—can lead to products being rejected during preparation. These rejections, even though the food is still safe and good, can cause significant waste. The study explored solutions like reusing meat trimmings in other products and increasing flexibility in product specifications.

AVEC

Product(s): Whole chicken, breast fillets, legs, poultry parts

Value Chain Stages: Primary production, Processing, Retail

Data Collection: in-depth interviews, surveys

This European case study focuses on poultry meat, working with companies across several countries. Often, whole chickens or specific cuts are rejected if they don’t meet grading standards—even though the meat is perfectly safe. AVEC examined how much poultry is downgraded or reprocessed and identified ways to reduce that waste. For example, creating clearer rules for certain parts (like feet or wings) and allowing more risk-based classification could help make better use of the full bird.

FEBEV

Product(s): Beef and pork carcasses, pre-packed meat, processed parts

Value Chain Stages: Slaughterhouse, Processing

Data Collection: in-depth interviews, surveys

FEBEV, the federation representing the Belgian meat sector, investigated how strict classification systems and customer requirements affect beef and pork products. A key finding was that large amounts of meat can be downgraded—or even wasted—if they don’t meet specific weight, shape, or colour expectations. The study looked at parts of the meat that are edible and nutritious but don’t meet marketing rules and explored whether these could be redirected into other uses like pet food, lower-cost meat products, or exports.

Cereal sector

Cereal-based foods—like wheat, oats, and corn—are staple ingredients in our diets, but strict food marketing standards related to protein content, moisture levels, or minor visual defects mean that even slight variations can push grains out of the food supply chain. In Italy and Slovenia, two small businesses are working to understand when and why grain is rejected and how more of it can be kept in use, especially in organic and plant-based food production.

Natura Nuova

Product(s): Soft wheat, corn, soy, flour

Value Chain Stages: Primary production, Processing

Data Collection: in-depth interviews

In Italy, Natura Nuova looked at how quality rules affect grains used in plant-based products like seitan, tofu, and tempeh. Some grains are rejected for minor issues—like discoloration or slightly lower protein content—and either sold cheaply or discarded. This case study found that strict expectations from buyers, especially for premium labels, can drive food waste even when the product is still usable. The team is exploring how to improve storage, sorting, and quality checks so that more grains can be kept in the food chain.

Vila Natura

Product(s): Wheat, oats, barley, corn, spelt

Value Chain Stages: Primary production, Processing, Food Service

Data Collection: in-depth interviews

This case focused on a Slovenian company that produces and processes organic grains. Despite their care for the environment, they still face food waste when grains don’t meet customer expectations—such as hectoliter weight or protein content. Some of this food is used as animal feed, but a lot is simply thrown away. Vila Natura is working to better track and sort their grains, and to find more buyers who accept slight variations in quality—especially for sustainable and organic products.

Eggs sector

At first glance, eggs seem like a simple product—but there’s a complex system behind them. Many are rejected during sorting, not because they’re unsafe, but because they have a crack, spot, or fall outside retail size food marketing standards. The BREADCRUMB egg studies in Denmark and across the EU explore how more flexible classification, modern processing, and clearer communication could allow more eggs to be used for food—and less to go to waste.

Landbrug & Fødevarer

Product(s): Shell eggs, Egg products

Value Chain Stages: Primary production, Packing station, Processing

Data Collection: in-depth interviews

In Denmark, most eggs are sorted and classified before reaching stores. Only the most visually perfect eggs—without cracks or marks—can be sold as top-grade products. Others are sent to processing plants or even discarded. This case study explored whether some of these eggs could be revalued or used more efficiently. One key debate is around washing eggs, which is currently not allowed in EU (except Sweden). The Danish team believes that modern cleaning techniques could make more eggs marketable and reduce unnecessary waste—without compromising safety.

Ilvo

Product(s): Eggs

Value Chain Stages: Primary production, Packing station, Processing

Data Collection: in-depth interviews

This cross-country study is gathering insights from egg producers, packing stations, and processors to understand where and why food waste occurs in the egg sector. Looking at the egg sorting process, eggs are often degraded due to size, leaks, cracks, and blood spots. The study also investigates how different food marketing standards influence the number of eggs that are downgraded or lost. Furthermore, a closer look was taking at the handling and management of these downgraded eggs. The goal is to use these insights to reduce waste across the sector, ensuring fewer eggs go to waste.

Fish sector

In the wildcaught fishing industry, food waste often begins before the fish even reaches land. Strict food marketing standards related to size, species, or appearance—as well as unpredictable weather and market demand—mean that a significant part of the catch is either discarded or sold at low value. In this case study from Spain, BREADCRUMB explored how the fish supply chain—from boat to retailer—can become more flexible and resilient. The study focuses on the gap between what is caught and what consumers expect, and how better traceability, awareness, and product valorisation can help turn undervalued species into valuable food.

OPPPB

Product(s): Sardines, anchovies, shrimp, lesser-known species

Value Chain Stages: Primary production, Wholesaler, Retail, Food service

Data Collection: in-depth interviews

Along Spain’s coast, fishers often land species that are safe and nutritious but overlooked by supermarkets—especially smaller or less familiar varieties. As a result, some are discarded or sold at very low prices, particularly if damaged or irregular in size. This case study followed the journey of these fish through the hands of fishers, wholesalers, retailers, and restaurants to find out where and why waste occurs.

Two major factors emerged: weather and species preference. Bad weather reduces supply and raises prices, helping most fish sell. But on calm days with big catches, prices can plummet, and less popular fish are often left behind. While favourites like sardines and anchovies consistently sell, species like chub mackerel and boga are more likely to be wasted due to low consumer demand.

The study highlights the potential of better traceability, flexible standards, and educating buyers about lesser-known fish as key steps toward reducing waste and improving the sustainability of the seafood sector.